Industrial Fasteners

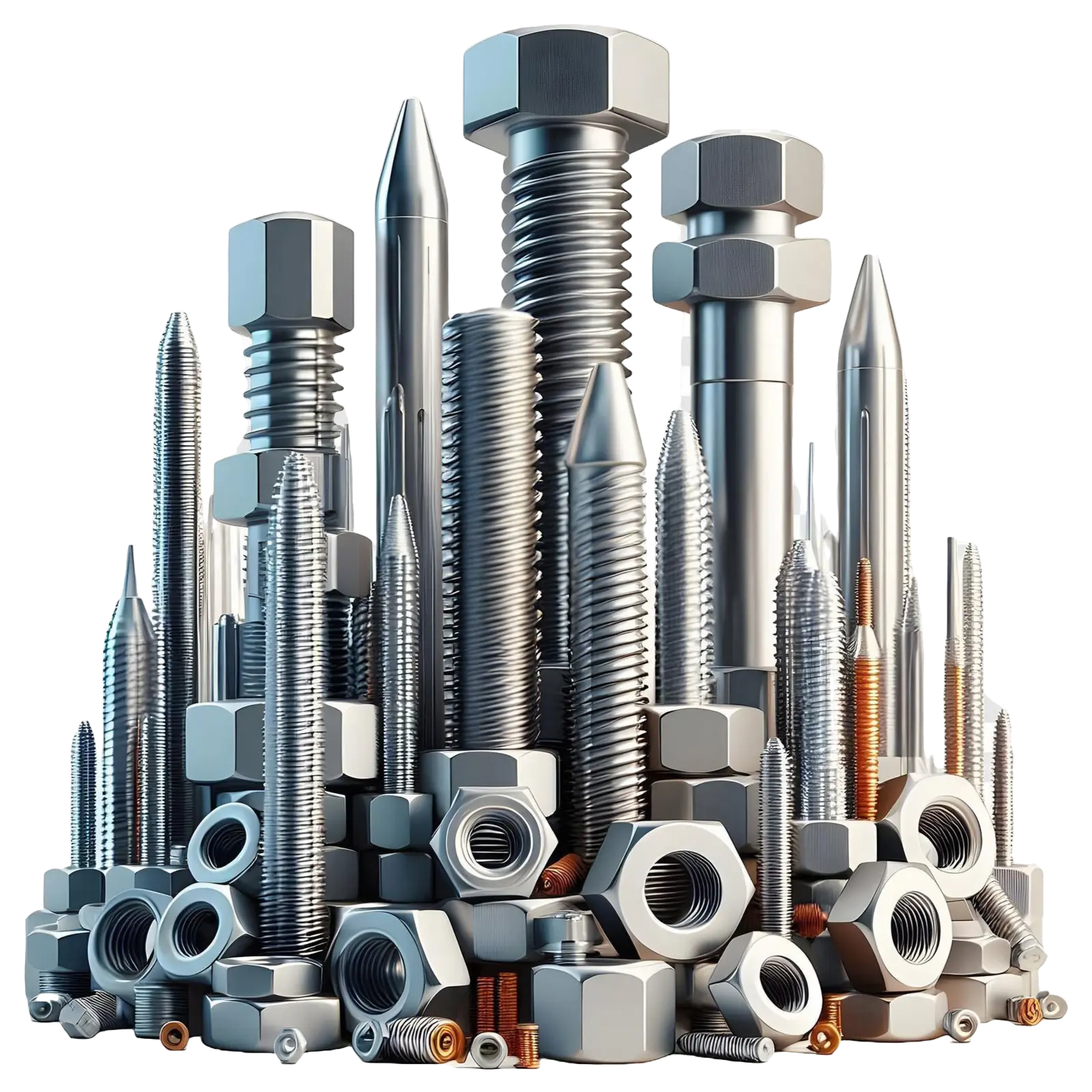

Fasteners are hardware components used to mechanically join or affix two or more objects together.

Fasteners are hardware components used to mechanically join or affix two or more objects together. They are widely used across industries, including construction, automotive, aerospace, and manufacturing.

Types of Fasteners

Fasteners come in various types, including:

- Bolts & Screws: Used in high-strength applications, available in different head types (hex, socket, Phillips).

- Nuts & Washers: Complement bolts and screws, ensuring a secure grip.

- Rivets: Permanent fasteners used in aerospace and structural applications.

- Anchors: Used in masonry and concrete fastening.

- Pins & Clips: Provide quick assembly and disassembly in mechanical applications.

Materials Used

Common materials for fasteners include:

- Steel (Carbon, Alloy, Stainless): Most widely used for strength and corrosion resistance.

- Brass & Bronze: Used in marine and electrical applications for corrosion resistance.

- Titanium & Aluminum: Lightweight, high-strength materials for aerospace and automotive.

Selection Criteria

When choosing fasteners, consider:

- Load-bearing capacity

- Corrosion resistance

- Environmental conditions

- Material compatibility

- Ease of installation and removal

Coatings & Treatments

To improve durability, fasteners undergo surface treatments such as:

- Zinc Plating: Protects against corrosion.

- Black Oxide: Enhances appearance and mild corrosion resistance.

- Galvanization: Provides strong rust protection for outdoor use.

- Heat Treatment: Enhances hardness and tensile strength.

Standards & Specifications

Common standards governing fasteners include:

- ISO (International Organization for Standardization)

- DIN (German Institute for Standardization)

- ANSI (American National Standards Institute)

- ASTM (American Society for Testing and Materials)

Industrial Applications

Fasteners are essential in:

- Automotive & Aerospace: Used in engines, body panels, and structural frameworks.

- Construction & Infrastructure: Securing steel beams, pipelines, and concrete structures.

- Electronics & Appliances: Assembly of circuit boards and enclosures.

- Oil & Gas Industry: High-pressure pipeline joints and heavy-duty connections.

Allen Bolts

Allen bolts, also known as socket head cap screws, are high-strength fasteners featuring a cylindrical head and a hexagonal socket drive. They are designed for use with an Allen wrench (hex key), providing superior torque and a secure fit.

Types of Allen Bolts

- Socket Head Cap Screws (SHCS)

- High-strength bolts used in machinery, automotive, and structural applications.

- Available in standard (DIN 912) and low-profile versions.

2. Button Head Socket Cap Screws

- Rounded, low-profile head for aesthetic and space-saving applications.

- Used in enclosures, electronics, and lightweight assemblies.

3. Flat Head Socket Cap Screws

- Countersunk design for a flush surface finish.

- Ideal for aerospace, woodworking, and precision applications.

4. Shoulder Bolts (Stripper Bolts)

- Features a cylindrical, smooth “shoulder” section for moving parts.

- Used in mechanical linkages, die sets, and automation systems.

5. Low Head Socket Cap Screws

- Reduced head height for tight-space applications.

- Commonly used in robotics and compact machinery.

From concept to creation : Fastening solutions for every Industry

Welcome to M/s. HK Sales, a reliable and customer-focused provider of industrial fasteners and components. Established in 2024 and based in Chakan, Pune, we specialize in offering high-quality fastening solutions that cater to a wide range of industrial applications.